Unlike modern hard disks with hydrodynamic ball bearings, old hard disks were pretty noisy, especially the firsts 7200 rpm units. My IBM Deskstar 60 GXP 40 GB was one of them. I also had a Maxtor 5400 rpm unit (not yet broken) not very noisy that I decided to silence as well.

Building and assembling

My first idea was to use rubber sticks sold in stores for this specific goal (they should replace the metal screws in order to decouple the hard disk from the chassis), but they had two defects: they cost a lot and they were too big to be put in my metal frame. I decided to use a rubber strip cut from a bycicle inner tube I had unused. I showed to be strong and perfect for this goal.

Every hard disk needs two rubber strips. I cut four of them, all about 3.5 cm large, two of them 10-12 cm long and the other two 20-25 cm long. The height is fixed: their width should be about 1 cm greater than the hard disk height and the length at least about 5 cm greater then the metal case where the hard disk is mounted: the hard disk must not touch the metal at all. Another choice is to have the strips about two times longer than the metal frame,in order to be put all around it (more about this later). The last tip is to cut the strip following the main inner tube equator: it's the only way to have them perfectly straight, not bended.

It's already clear that my idea was to put the rubber between the hard disk and the frame, however it showed to be not so easy, especially for the Maxtor hard drive, the upper one in the pictures.

To put the rubber around the IBM hard disk, I followed this sequence (there was not much space to move): I removed the hard disk and completely removed the screws (they would't have been used anymore). I then put the rubber strips on its sides (I chose the two smallest among the four I mentioned before). These two strips should be longer than the hard disk, so the exceeding rubber was left on the front of the hard disk (where there are no connectors), on the side the hard disk moves towards when you mount it. Now it's time to put the hard disk back in place, but it won't be easy: the rubber not only increased the hard disk's width, but it also increased friction a lot. I solved the problem by having someone widen the metal case of the chassis. Also remember to give a look at the vertical position of the rubber: it must avoid every contact between the hard disk and the metal frame of the chassis.

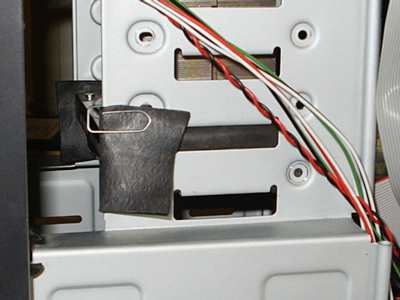

The final result should be something similar to the following:

The clip helps to block the rubber and to avoid a change in the air flow inside the chassis (it's not so good in my computer), while the heatsink visible n the picture is what I described in How to apply a heatsink to an IBM hard disk.

To put the rubber around the Maxtor I followed a different sequence: I chose longer strips, so long I was able to block them outside the chassis with some staples. To do this I also had to strain them, so they were thinner and the hard disk slipped in more easily.

The next picture show the final result and the following one both the hard disks. The latter shows perfectly how the rubber must be positioned vertically: it covers completely the hard disks sides and, partially, top and bottom faces.

The effect of these modifications really satisfied me: the noise was greatly reduced. Probably the drives will experience an increased working temperature, since the metal frame of the chassis does not dissipate anymore the heat generated by the hard disks, but the are still running cool, so it's not a problem.

If you need help or more informations, feel free to ask me by mail.

Author: Olaf Marzocchi